Features:

- Noise reduction 5 to 15 dBA

- Quick access to machinery and equipment

- Custom-engineered systems to fit your application

- Easy to install, relocate, and modify

- Fire safe with low smoke emissions

- Roof panels and ventilation systems available

- Optional observation windows

- Long service life

Curtain Systems

REDUCE THE TRANSMISSION OF MACHINE-GENERATED NOISE WITHOUT HAMPERING WORKER ACCESS TO THE MACHINERY.

Moderate industrial noise control problems (requiring 5-15 dBA noise reduction) can often be solved with McGill AirSilence's flexible acoustical curtain systems. Made of durable panels, our curtain systems are designed for the toughest industrial environments. Whether acting as full or partial enclosures, machinery shrouds and hoods, partitions, or barrier walls, they reduce the transmission of machine-generated noise without hampering worker access to the machinery.

McGill AirSilence offers three main types of panels for its acoustical curtain systems: double-layer blocking, single-layer blocking, and absorption. Transparent panels are also available.

McGill AirSilence offers three main types of panels for its acoustical curtain systems: double-layer blocking, single-layer blocking, and absorption in thicknesses of 1, 2, and 4 inches. Transparent panels are also available. Fibersorb acoustical curtain systems are sized and configured to meet the specifications of each application.

DOUBLE-LAYER BLOCKING PANELS

The versatile double-layer blocking panel is ideal for isolating multiple noise sources located on both sides of the panel. It consists of a vinyl barrier sandwiched between two layers of 1-inch-thick fiberglass insulation. The double-layer blocking panel absorbs noise and blocks transmission of sound coming from both sides of the curtain.

SINGLE-LAYER BLOCKING PANELS

The single-layer blocking panel is ideally suited for isolating a noise source located on one side of the curtain system. A single-layer panel is designed with 1-inch fiberglass insulation sewn into one side of a vinyl barrier. The insulation absorbs noise, and the vinyl barrier blocks its transmission to other areas.

ABSORPTION PANELS

The absorption panel does not block noise; it only absorbs it. The system consists of 2-inch quilted fiberglass panels that are usually attached to an existing wall or barrier to reduce reverberant noise.

An alternative to McGill AirSilence's free-hanging acoustical curtains are our mobile acoustical barrier screen, wall panels, and overhead ceiling baffles.

ACOUSTICAL BARRIER SCREEN

Standard acoustical barrier screens run 4 feet wide by 8 feet high, but custom-made screens are available. The screen consists of an 18-gauge steel frame with supporting legs and curtain panels which are fastened to the top of the screen with grommets. Barrier screens are an effective means of noise control where mobility is desired.

ROLL GOODS

- Curtain material is available in 25- to 50-foot lengths (custom sizing available)

- Standard width — 48 inches (custom sizing available)

- Available with bound and sewn finished edges or unbound edges

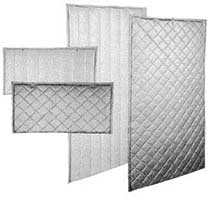

CURTAIN WALL PANELS AND OVERHEAD BAFFLES

Curtain wall panels and overhead baffles are availabe in the same panel materials and types as our standard curtain systems. Standard sizes are 4 feet wide by 8 feet long.

- Reduce reverberation

- Add sound absorption

- Lower noise levels

- Tone room, and turn hard reflective surfaces into soft, sound-absorptive surfaces

- Improve communication

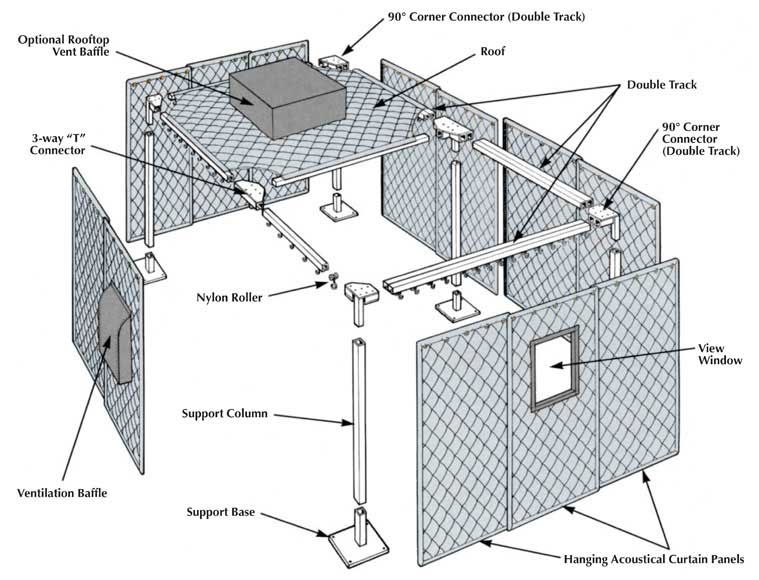

CURTAIN SUPPORT FRAMEWORK

- Standard curtain track and hardware system is manufactured from heavy-gauge galvanized steel components

- Floor-mounted, beam-mounted, suspended, wall-mounted, and ceiling-mounted styles are available

- Double-track configuration allows for slide-by access at any point

- Curved corner options allow for even greater access

- Type H-D heavy-duty frame (optional) features structural steel tubing for maximum strength to accommodate larger enclosures.

Typical Assembly of a Fibersorb™ Acoustical Curtain Enclosure

Absorber and Barrier Curtain System Use Factors

- MODEL SC

Total and partial enclosures, shrouds, and hoods. Noise source on one side. Noise reduction objectives: 10-201 dBA. Maximum curl, tear abuse resistance.

- MODEL SC-2

Total and partial enclosures, shrouds, and hoods. Noise source on one side. Best product combining the durability of a 1 lb/sq ft reinforced acoustical barrier with a 2-inch-thick faced fiberglass absorber offering maximum performance (STC=32, NRC=0.75). Noise reduction objectives: 20-251 dBA.

- MODEL DC

Separator walls and divider partitions. Noise source on both sides. Maximum performance (STC=33, NRC=0.75). Noise reduction objectives: 20-251 dBA. Barrier septum 2 lb/sq ft.

- MODEL DC-2

Separator walls and divider partitions. Noise source on both sides. Noise reduction objectives: 10-201 dBA. Most economical of both styles employing 1 lb/sq ft flexible barrier and 2-inch absorber. Passes ASTM E84-84a; Class 1 fire rating.

1Actual noise reduction can vary with application and may exceed these values.